What are the 5 elements of injection molding?

超级管理员

Views:35

Release time:2024-04-25

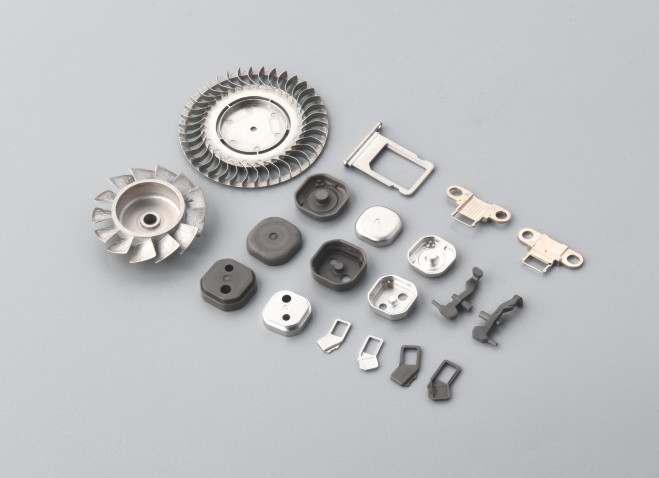

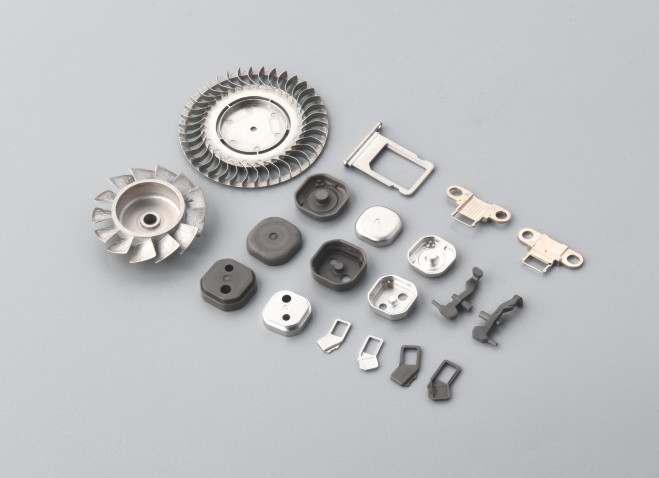

The five critical elements of injection molding are:

Material: Understanding the properties of the plastic material to be used is crucial. These properties include melt temperature, molding temperature, molding pressure, and shrinkage rate. All these factors greatly influence the final result.

Mold Design: The design of the mold determines the shape, size, and features of the molded part. Factors like number of cavities, type of gate, cooling system design, as well as the materials used are considered.

Molding Machine: The injection molding machine supplies the plastic material, heats it until it reaches a viscous state, and then injects it into the mold. Various factors such as pressure, speed, and temperature must be controlled carefully.

Injection Process Parameters: This includes control and optimization of various machine parameters like injection speed, back pressure, clamp force, injection time, cooling time, etc. Regulation of such parameters is crucial for producing consistent, high-quality parts.

Operator's Skill: Even with automated machines, a skilled operator or technician plays a significant role in the injection molding process. From set-up and adjustments, to maintenance and troubleshooting, the operator's proficiency greatly influences the success of the process.