How is plastic mold manufacturer?

超级管理员

Views:152

Release time:2024-07-25

Plastic mold manufacturers play a crucial role in a wide range of industries by providing essential components that are used in the production of a diverse variety of products. Let's take a closer look at what plastic mold manufacturers do and what makes them integral to the manufacturing process:

Design and Engineering:

Product Design: Manufacturers often work closely with clients to develop product designs. This can involve creating prototypes and making adjustments to meet specific requirements.

Mold Design: The design of the mold itself is critical. This includes considering factors such as materials, dimensions, finish, and the number of cavities in the mold.

Material Selection:

Different plastic materials have unique properties that affect their moldability, durability, strength, and suitability for different applications. Manufacturers help select the appropriate type of plastic based on the end-use requirements.

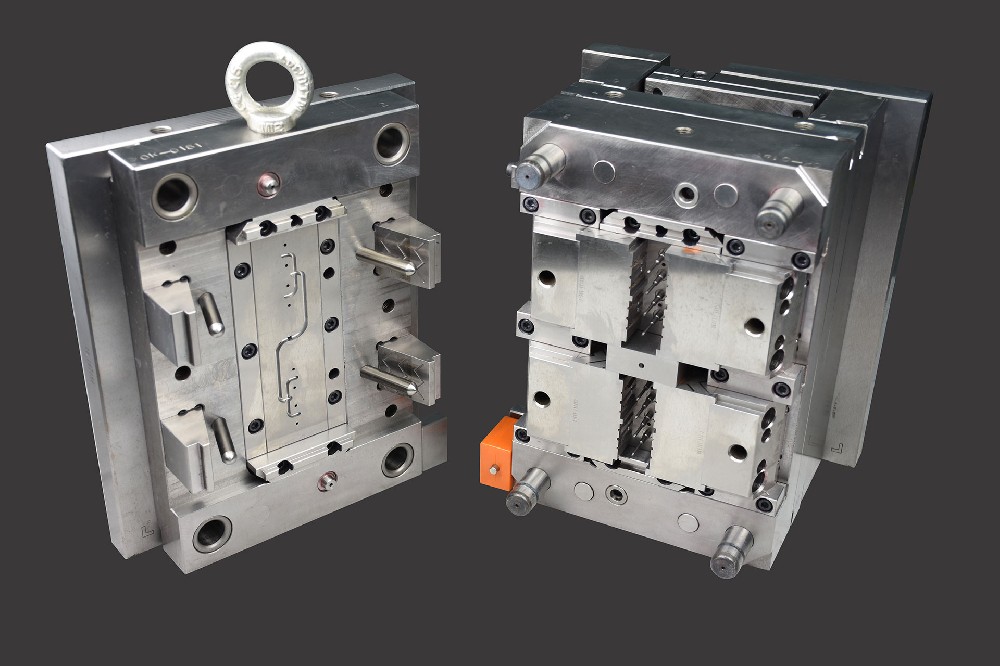

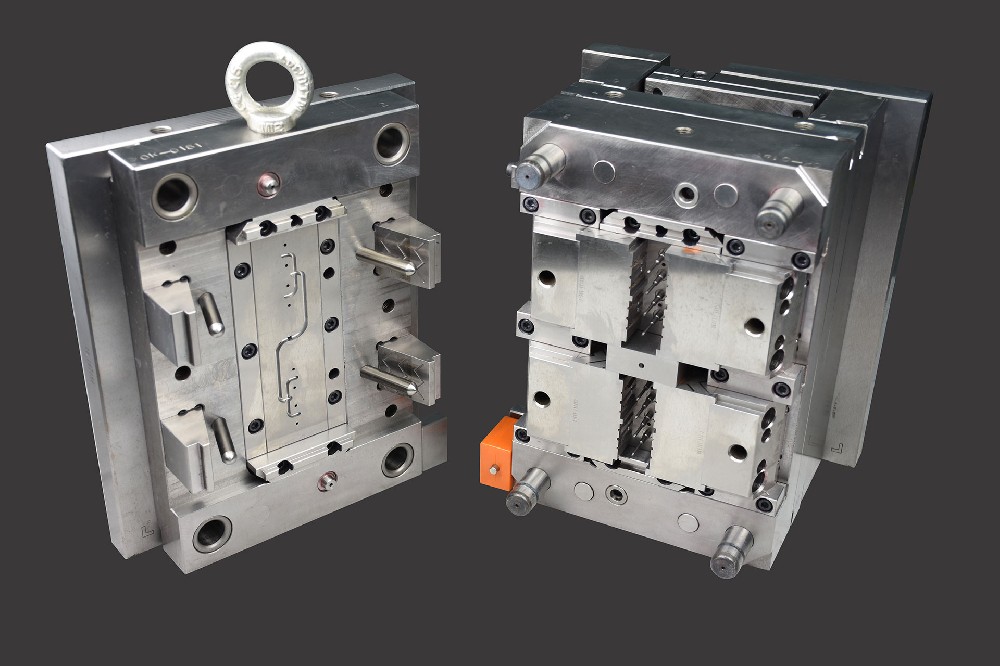

Mold Fabrication:

The actual creation of the mold involves precision engineering and machining. This may involve CNC machining, electrical discharge machining (EDM), and other processes.

Molds must be manufactured to exact specifications to ensure that the final plastic parts are accurate and consistent.

Injection Molding Process:

Setup: The mold is installed in an injection molding machine where plastic resins are heated until they become molten.

Injection: The molten plastic is injected into the mold where it cools and hardens into the desired shape.

Ejection: Once cooled, the plastic part is ejected from the mold, and the process can be repeated.

Quality Control:

Continuous monitoring during production ensures that each part meets the required specifications.

Post-production inspections might include dimensional checks, stress testing, and other quality assurance measures.

Maintenance and Longevity:

Precision and Consistency: High-quality molds produce parts with excellent precision, ensuring consistency across large production runs.

Customization: Molds can be customized for specific product designs, allowing for flexibility in manufacturing.

Efficiency: Injection molding is an efficient process that allows for high-volume production at a relatively low unit cost.

Material Versatility: A wide range of plastic materials can be used, each offering different properties and benefits.

Plastic mold manufacturers serve a vast array of industries, including:

Automotive: Components like dashboards, door panels, and engine covers.

Consumer Goods: Household items such as containers, utensils, and toys.

Medical: Products like syringes, medical instruments, and housings for medical devices.

Electronics: Cases and enclosures for electronic devices.

Packaging: Custom packaging solutions for various products.

In summary, plastic mold manufacturers are vital in transforming raw plastic materials into functional, precise parts used in countless products. Their expertise in design, engineering, and quality control ensures that products are produced efficiently, accurately, and cost-effectively.