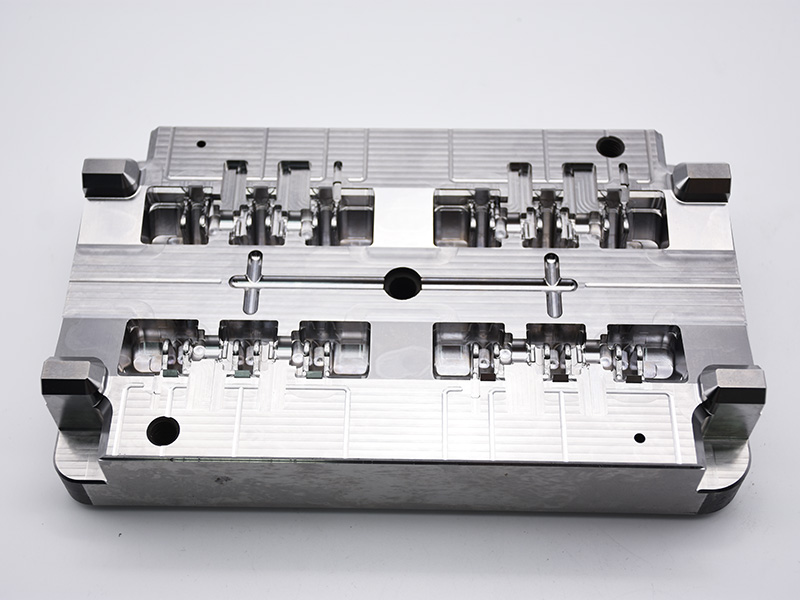

What is the introduction of injection molding?

Injection molding is a manufacturing process most commonly used with plastics, but it can also be used with other materials including metals and glass. The process involves injecting a material in its molten state into a mold to form a particular shape. It is widely used in mass production due to its ability to maintain consistent and high-quality output.

Last page:How do you inject mold parts?

Recommended reading

- -"5 Secrets to Perfect Mold Parts Every Time – #3 Will Shock You!"

2025-02-11 - -Injection mold processing, precision mold processing

2024-12-26 - -Why buy precision Injection Molding Spare Parts in China?

2024-12-16 - -Components of an Injection Mold

2024-11-25 - -High Precision Core Insert for Plastic Injection Mold

2024-11-05 - -What are the key steps in heat treatment and surface treatment of molds?

2024-10-31 - -Precision irrigation system mold cavities and mold parts play a crucial role in the manufacturing

2024-10-31 - -How to control the roundness and cylindricity of precision parts machining

2024-09-26 - -Definition and production of mold cavity in casting

2024-09-24 - -OKMOLD has a new look! Discover it at FAKUMA 2024

2024-09-23