Plastic mold manufacturer in China

Founded in 2004, Ok Mold Technology Co., Ltd is a professional high precision plastic mold components making company. Product refer to: micro-injection mold, medical, liquid silicone rubber, photoelectronics, new emerging Energy, auto harness, computer, cell phone connector, and so on.

Nowadays,Ok Mold have ability to do making very tight tolerance components that maybe found to be nearly impossible to achieve. Our grinding precision up to ±0.001mm, wire cutting precision up to ±0.002mm, EDM precision up to±0.002mmmm, CNC machining precision up to ±0.002mm.

With more than 10 year’s development, Okmold obtained ISO9001:2008 Certification in 2012 and translated our precision components making experiences into mold making industrial. Ok Mold now has became a reliable manufacturer could provide full service of plastic parts making which cover high precision mold components making, engineering design, plastic injection mold making, molding, second processing and so on.

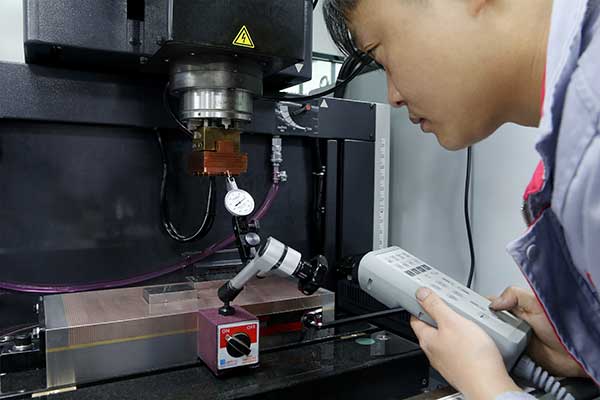

Okmold equipped with a number of state-of-art processing equipments such as Roders &DMG MORI high speed CNC machine, Mitsubishi & Sodick High precision EDM machine, Seibu&Sodick slow speed Wire Cutting machine etc., What’s more, our 40 skilled &diligent technicians are pretty familiar with the performance (advantage, disadvantage and machine error) of our machines. Mastering lots of proprietary skills to improving the precision of mold making such as cuter selection, customize programming, and human-machine synergetic. Constantly sum experience and proprietary skills make us ability to making parts exceed the precision of machine itself.

Professional engineers and precision machining make us ability to make the mold components with 0.001mm(micro) lever tolerance. Currently, our grinding precision up to ±0.001mm, wire cutting precision up to ±0.002mm, EDM precision up to±0.002mm, CNC precision standard up to ±0.002mm.

Okmold is ability to making very tight tolerance parts that may be found to be nearly impossible to achieve.

Human-machine synergetic is the key to extreme precision mold making for Okmold.

What is human-machine synergetic?

Human-machine synergetic is a method for eliminating machine error to improving machine precision. For example, when we making some part on a machine with theoretical numerical of 100mm, but the actually numerical was come out with 99.99mm. We will record it, sum up it and learn from it. When we want to get the actual numerical of 100mm with this machine next time, we will input the theoretical numerical 100.01. The machine error was modify by human-machine synergetic.

Last page:What is an insert in die casting?

Recommended reading

- -"5 Secrets to Perfect Mold Parts Every Time – #3 Will Shock You!"

2025-02-11 - -Injection mold processing, precision mold processing

2024-12-26 - -Why buy precision Injection Molding Spare Parts in China?

2024-12-16 - -Components of an Injection Mold

2024-11-25 - -High Precision Core Insert for Plastic Injection Mold

2024-11-05 - -What are the key steps in heat treatment and surface treatment of molds?

2024-10-31 - -Precision irrigation system mold cavities and mold parts play a crucial role in the manufacturing

2024-10-31 - -How to control the roundness and cylindricity of precision parts machining

2024-09-26 - -Definition and production of mold cavity in casting

2024-09-24 - -OKMOLD has a new look! Discover it at FAKUMA 2024

2024-09-23